“Versatile Hot Stamping Process for Fabrics: Fading and Glue Issues Persist”

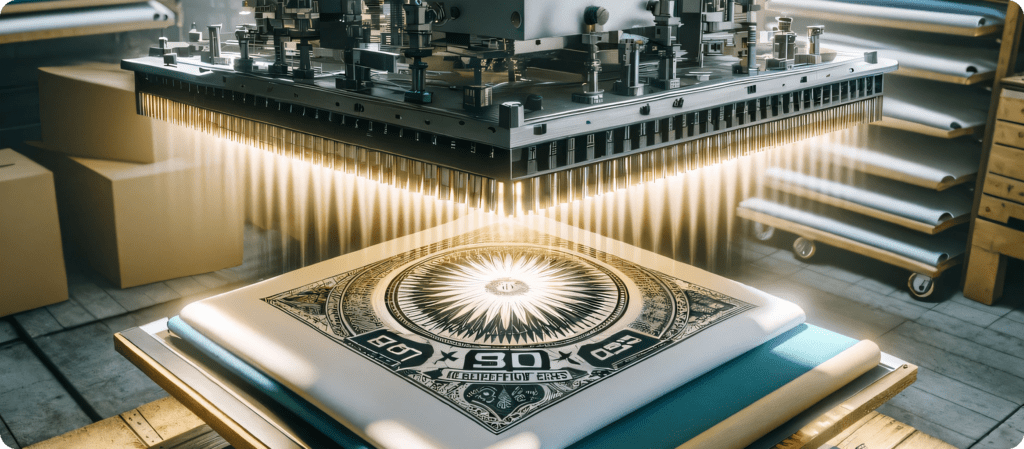

As the name implies, hot stamping involves the use of DTF ink to print patterns on PET film, along with white ground glue and resin glue, and subsequently hot-stamping the design onto fabric. If a layer of rubber is applied, the end result is a smooth-feeling, brightly-colored, clear, and realistic pattern that can be used on a variety of fabrics such as cotton, polyester, knits, non-wovens, leather products, and luggage materials, among others.

Regarding the hot stamping process, compared to the previous sublimation transfer technology, the advantage of hot stamping is that it can be applied to cotton, knit, and other fabrics. However, the downside is that the clothing material can change significantly, and it’s apparent that there’s a layer of glue on the fabric. Additionally, the pattern may fade easily, and the color fastness isn’t very high.

There are various ways of heated stamping methods, which can be in general classified into first tear, cold tear, and hot tear processes. Glass bead hot stamping falls under the first tear process. Before hot stamping, the pattern is torn off from the PET film and positioned on the fabric to be printed.

Cold tear processes include bright side hot stamping, matte side hot stamping, flocking hot stamping, gold and silver foil hot stamping, reflective hot stamping, crystal illusion color hot stamping, and pure gold onion hot stamping. In cold tearing, the hot stamping machine alarms, and after lifting the machine, the fabric and the stuck hot stamping pattern are removed and allowed to cool before tearing it off.